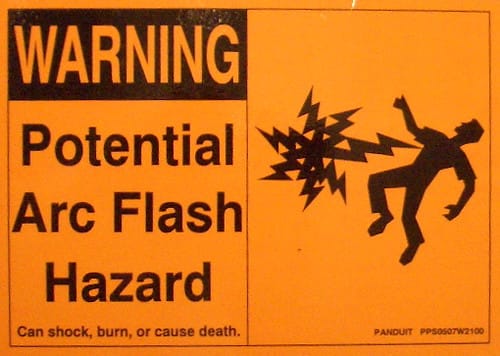

Arc flash PPE (Personal Protective Equipment) is critical for protecting workers from severe injuries caused by electrical arc flashes. Understanding when arc flash PPE is required helps ensure safety, compliance with regulations, and effective risk management in hazardous environments.

Arc flash PPE is required whenever a worker is within the arc flash boundary of energized electrical equipment. OSHA and NFPA 70E provide guidelines and standards for determining the type and level of PPE based on hazard risk categories and incident energy levels.

To fully grasp when arc flash PPE is necessary, we’ll examine regulatory guidelines, PPE categories, potential consequences of non-compliance, and the protective materials used in this specialized equipment.

What are the OSHA guidelines for requiring arc flash PPE?

OSHA mandates the use of arc flash PPE to protect workers from electrical hazards in compliance with industry standards like NFPA 70E.

OSHA requires arc flash PPE when workers perform tasks near energized electrical equipment that poses arc flash risks. Employers must conduct hazard assessments to determine PPE needs.

The Occupational Safety and Health Administration (OSHA) doesn’t directly prescribe arc flash PPE requirements but enforces general safety regulations under 29 CFR 1910 Subpart S. Employers are required to:

- Perform Hazard Assessments: Identify tasks and environments where arc flash risks exist.

- Establish Safe Work Practices: Implement boundaries, de-energize equipment when possible, and provide appropriate PPE.

- Follow NFPA 70E Standards: Adopt industry standards for hazard classification and PPE selection.

Arc Flash Boundary

OSHA also emphasizes determining the arc flash boundary—the distance within which PPE is mandatory. Workers operating inside this boundary must wear PPE rated for the incident energy level.

What types of arc flash PPE are required for different hazard categories?

Arc flash PPE requirements vary based on the hazard category, which is determined by the level of incident energy exposure.

NFPA 70E defines four hazard categories, each specifying the required arc flash PPE, from basic fire-resistant clothing to advanced multi-layered suits.

PPE requirements are categorized into four levels, based on incident energy (measured in calories/cm²):

| Category | Incident Energy Level | Required PPE |

|---|---|---|

| Category 1 | 1.2 to 4 cal/cm² | Flame-resistant (FR) shirt and pants, arc-rated helmet or face shield |

| Category 2 | 4 to 8 cal/cm² | Full FR clothing, including a jacket, pants, and gloves |

| Category 3 | 8 to 25 cal/cm² | Multi-layer arc-rated suit, insulated gloves |

| Category 4 | 25 to 40+ cal/cm² | Heavy-duty arc flash suit with hood, gloves, and boots |

Workers performing tasks like breaker operation, troubleshooting, or maintenance near energized equipment must adhere to these PPE levels to mitigate risks.

What are the consequences of not wearing arc flash PPE when required?

Failure to wear arc flash PPE can result in severe injuries, regulatory penalties, and legal liabilities for employers.

Not wearing arc flash PPE can lead to life-threatening burns, electrocution, and financial consequences, including fines and lawsuits for non-compliance.

The consequences of not wearing arc flash PPE when required can be devastating, including:

- Physical Injuries: Arc flashes generate extreme heat (up to 35,000°F), causing third-degree burns, blindness, or fatal injuries within milliseconds.

- Legal Penalties: OSHA fines for failing to provide or enforce PPE can range from thousands to hundreds of thousands of dollars per violation.

- Loss of Productivity: Injuries disrupt operations, resulting in downtime and higher costs for employers.

- Insurance Impacts: Workplace accidents can lead to increased premiums or denied claims if PPE protocols are ignored.

By ensuring PPE compliance, employers can protect their workforce and avoid these risks.

How does the choice of materials in arc flash PPE enhance protection?

The materials used in arc flash PPE determine its protective capabilities, durability, and comfort for workers.

Advanced materials like Nomex, Kevlar, and specialized fabrics provide superior heat resistance, durability, and comfort in arc flash PPE.

Materials play a crucial role in arc flash PPE effectiveness. Common materials include:

- Nomex: A flame-resistant, lightweight fabric known for durability and comfort in Category 1 and 2 PPE.

- Kevlar: Provides exceptional heat resistance and is often used in gloves and multi-layered suits for higher categories.

- Aluminized Fabrics: Reflect radiant heat, ideal for heavy-duty arc flash suits in Category 3 and 4 environments.

- Moisture-Wicking Liners: Enhance comfort by reducing sweat accumulation during extended wear.

These materials are chosen based on the level of incident energy and the environmental conditions, ensuring optimal protection without compromising mobility or comfort.

Conclusion

Arc flash PPE is a critical safety measure for workers exposed to electrical hazards. OSHA and NFPA 70E standards provide clear guidelines for determining when and what type of PPE is required. By understanding the risks, adhering to hazard categories, and selecting advanced materials, employers can ensure their workforce is protected against arc flash incidents.

Zion Zhang

Recent Posts

Color Consistency: The Delta-E Standard and the End of the “Clown Suit” Effect2026年2月4日In the corporate world, a uniform is a brand’s […]

Color Consistency: The Delta-E Standard and the End of the “Clown Suit” Effect2026年2月4日In the corporate world, a uniform is a brand’s […] Why Zippers Fail (and How We Prevent It): The Engineering of Closure Reliability2026年2月4日In the hierarchy of industrial garment components, the […]

Why Zippers Fail (and How We Prevent It): The Engineering of Closure Reliability2026年2月4日In the hierarchy of industrial garment components, the […] The Anatomy of a Seam: Engineering Durability at the Needle Point2026年2月4日In the world of industrial workwear, the fabric gets all […]

The Anatomy of a Seam: Engineering Durability at the Needle Point2026年2月4日In the world of industrial workwear, the fabric gets all […] Future Lab PPE Trends: The Convergence of Lightweight Protection & Sustainability2026年1月28日In the sterile corridors of pharmaceutical R&D, biotech […]

Future Lab PPE Trends: The Convergence of Lightweight Protection & Sustainability2026年1月28日In the sterile corridors of pharmaceutical R&D, biotech […] Chemical Protection Classes A/B/C: The Definitive Guide to Risk-Based PPE Selection2026年1月28日In the hazardous materials (HazMat) industry, […]

Chemical Protection Classes A/B/C: The Definitive Guide to Risk-Based PPE Selection2026年1月28日In the hazardous materials (HazMat) industry, […] Freezer Gloves & Boots Trends: The Intersection of Thermal Physics and Grip Technology2026年1月28日In the unforgiving environment of a -30°C cold storage […]

Freezer Gloves & Boots Trends: The Intersection of Thermal Physics and Grip Technology2026年1月28日In the unforgiving environment of a -30°C cold storage […]

CONTACT US

- Feel free to contact us any time. We will get back to you as soon as we can!

- +86-17330061805